Home >> News >> Product News

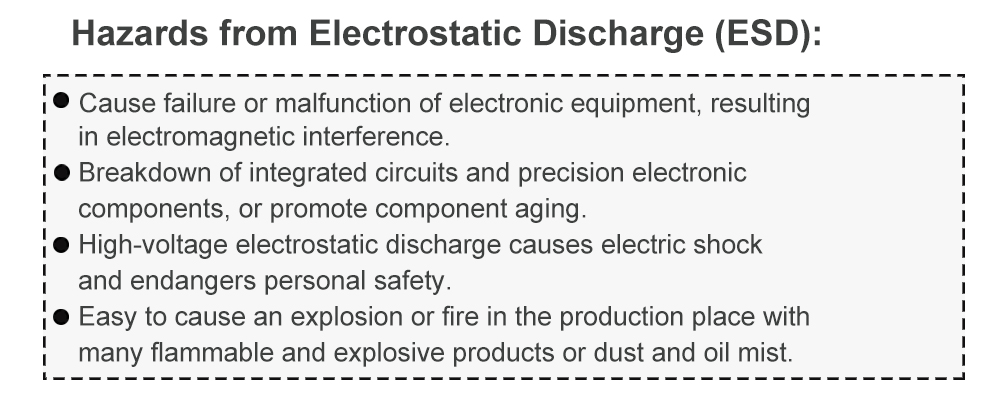

In physics, static electricity can be generated when any two objects of different materials contact and then separate, and the most common way is friction. While static electricity which seems insignificant will do badly harm to electrical equipment in the production process. It will break down integrated circuits and precise electronic components when discharged, and damage the components directly. In addition, static electricity always attracts dust, causing pollution of integrated circuits and semiconductor components, causing short circuits, or reducing the insulation performance of devices.

The structural characteristics of electronic components are delicate and tiny. it takes much time and effort to detect once damage occurs, what's more, some electrostatic damage phenomena are difficult to distinguish. Prevention is far more effective than remedy, so a compliant production environment with Strict production processes and procedures is very important.

We attach great importance to the anti-static work during production and we have a complete anti-static workshop. We build a human body electrostatic discharger at the entrance of the workshop, it can destaticizing in 3 seconds, and anti-static rubber sheets are placed on the operation stations such as assembly, welding, repairing, and debugging. Workers must wear anti-static wrist straps before the operation. Strict requirements aim to produce more PoE products that meet customer standards.